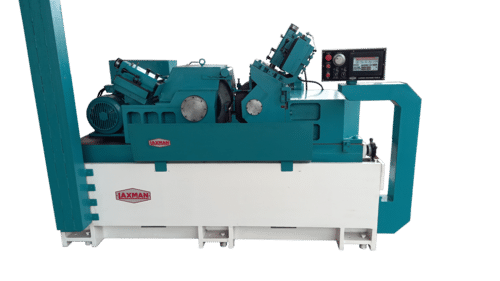

Centerless Grinder LM 5030

Product Details:

- Type Feed Grinding Machine

- Weight (kg) 5000 Kilograms (kg)

- Automatic Yes

- CNC Or Not CNC

- Control System PLC Control

- Grinding Wheel Size 500

- Grinding Wheel Speed 35 m/s

- Click to View more

Centerless Grinder LM 5030 Price And Quantity

- 1 Unit

- 3000000 INR/Unit

Centerless Grinder LM 5030 Product Specifications

- High Performance High Efficiency

- PLC Control

- 35 m/s

- 300

- CNC

- 5000 Kilograms (kg)

- 500

- Yes

- Feed Grinding Machine

Centerless Grinder LM 5030 Trade Information

- North America Middle East Western Europe Africa Central America Eastern Europe Australia South America Asia

- All India

Product Description

A type of grinding machine called a centerless grinder is used for finely grinding cylindrical workpieces. It is frequently used for high-precision grinding operations in the manufacturing and machining industries.

Here are some centerless grinder characteristics and factors to remember:

1. Workpieces are ground between a grinding wheel and a regulating wheel in centerless grinders. While the regulating wheel regulates the workpiece's rotational speed and feed rate, the grinding wheel removes material from the workpiece. The workpiece is supported by a blade on the work rest, therefore centering is not necessary.

2. Different cylindrical workpiece types, including solid bars, tubes, pins, shafts, and other parts, can be ground with centerless grinders. They are capable of working with a variety of materials, including brass, aluminium, steel, stainless steel, and more.

3. Precision and Accuracy: Centerless grinders are renowned for their capacity to attain extremely high standards of precision and accuracy. Tight tolerances and a great surface finish on the ground workpieces are made possible by the design. They have the ability to retain constant roundness when grinding to exact sizes.

4. Versatility: Centerless grinders are flexible when it comes to grinding uses. Depending on the unique requirements of the workpiece, they can be configured for a variety of grinding procedures, including through-feed grinding, in-feed grinding, and plunge grinding.

5. Automation: For automated control of grinding processes, many contemporary centerless grinders use CNC (Computer Numerical Control) technology. Precision, productivity, and repeatability are all improved by programmed control over grinding parameters provided by CNC automation.

6. Efficiency: Centerless grinders are made for continuous, high-speed grinding, increasing total output. They can manage large numbers of workpieces, cutting setup times and boosting productivity.

Since they offer precise and effective grinding solutions for cylindrical workpieces, centerless grinders are essential instruments in precision grinding applications. They are crucial in numerous manufacturing and machining operations because of their adaptability, automation, and capacity for achieving precise tolerances.

FAQ

1. What kind of machining capability does the LM 5030 offer, specifically?

Ans - The centerless grinding capabilities of the LM 5030 make it possible to efficiently and precisely grind cylindrical objects. Both centred and between centres can be ground by it.

2. What kinds of materials can the LM 5030 be used to machine?

Ans - Both ferrous and non-ferrous metals, such as carbon steel, stainless steel, aluminium, brass, and bronze, can be machined with the LM 5030.

3. How much material can the LM 5030 handle in terms of length?

Ans- Parts up to 10" long can be accommodated by the LM 5030.

4. What is the largest diameter of a part that the LM 5030 can machine?

Ans - Parts with a diameter of up to 3.5" can fit inside the LM 5030.

5. What kind of control system does the LM 5030 employ?

Ans - The Siemens S7-300 control system, which powers the LM 5030, offers dependable performance and accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Centreless Grinders' category

|

LAXMAN MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry